Product Development

KNIPPING NEW MOBILITY has the ability to cover the complete development of our humidifer in-house. This is also supplemented by our research partners and suppliers who are also closely involved in development. This covers everything from testing, simulation, industrialization and quality.

Design & Simulation

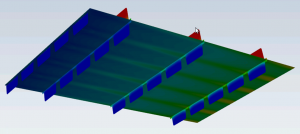

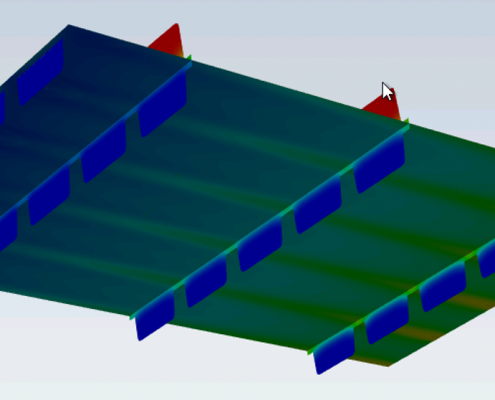

KNIPPING NEW MOBILITY has all capabilities in-house to develop a fuel cell humidifier. These capabilities can also be quickly expanded to other BoP components for the cathode side.

Team represents extensive system expertise in electrification both battery and fuel cell electric vehicles. Outstanding knowledge of BoP components guarantee state-of-the-art engineering.

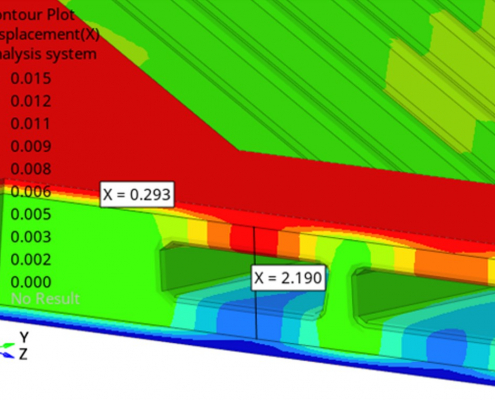

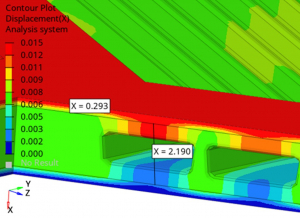

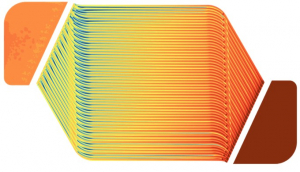

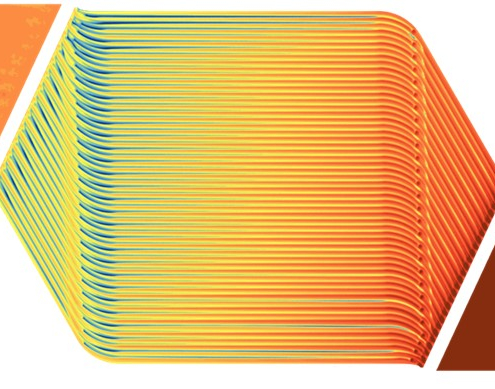

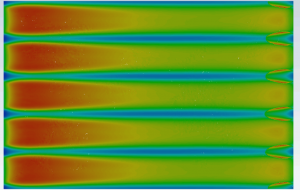

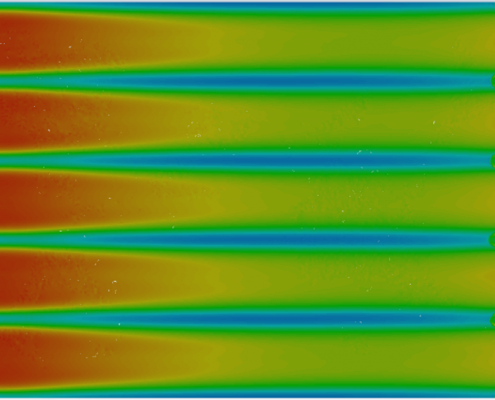

Simulation and modelling cover CFD, FEA and Moldflow expertise.

Testing & Validation

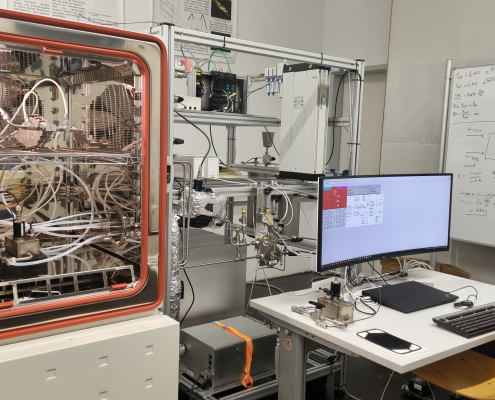

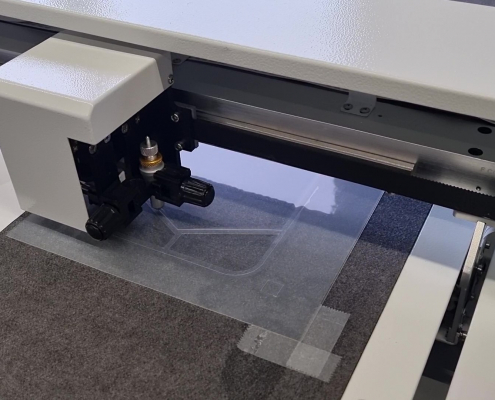

KNIPPING has invested in its own humidifier testing hardware. One example of this is the small-scale humidifier test stand which can test single cell and short stack humidifiers.

This small-scale test stand was designed and built to simulate the fuel cell stack inlet and outlet conditions of a large range of PEM fuel cell systems over a large range of power outputs.

This will allow KNIPPING to speed up the development process and more effeciently reach the requirements set by our customers.

With this test stand KNIPPING can optimise its humidifier design while also identifying the best performing water transfer membranes available on the market.

Some of the tests that can be carried out on the small-scale test stand are as follows:

- External and internal leakage at varying temperatures

- Flow field optimisation

- Membrane benchmarking

- Degradation and life cycle testing

- High/low temperature and freeze start testing

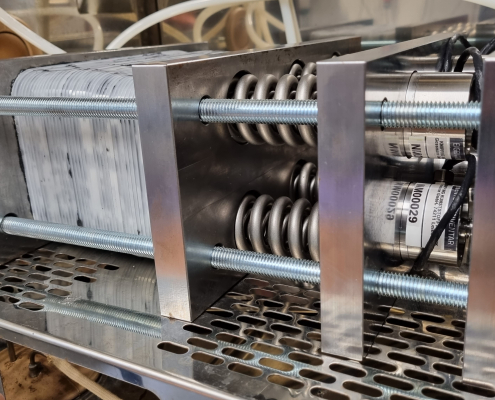

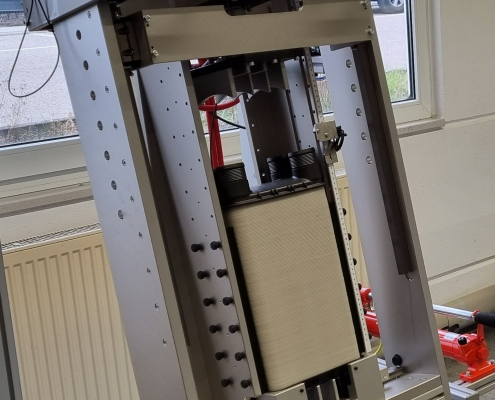

Prototyping

Innovative concepts move from an initial idea to a series component in KNIPPING’s Engineering Lab. This allows early testing and concept evaluation, feasibility assessment and translation readiness levels, rapid feedback and iterations to accelerate product development.

Workstations

- Inbound material inspection

- Material storage

- Distribution plate preparation

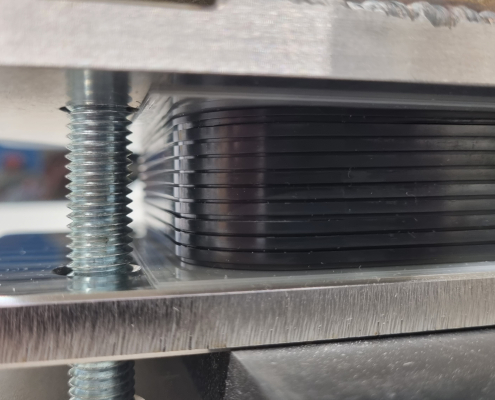

- Membrane/sealing cutting and preparation

- Stacking and housing

- End-of-line testing

- Packaging and outbound

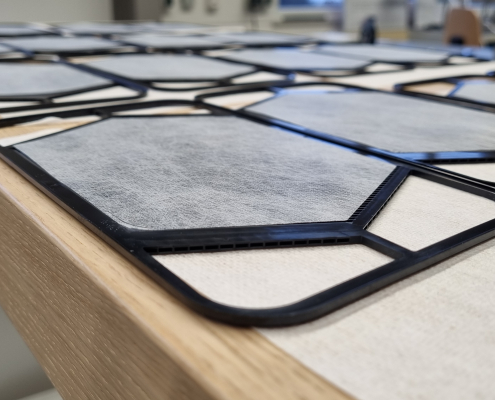

Well Connected

Many years of experience and expertise in thermal plastics are used in a variety of pioneering research projects in the humidification of PEM fuel cells. This enables us to continuously increase quality and productivity.

KNIPPING unites recognized suppliers and global manufacturing process partners on its development path of the humidifier. A key building block is the collaboration with our research partner, the University of Applied Science, Esslingen, Germany.

Get in touch with us

Dr. Martin Lenz

Director KNIPPING NEW MOBILITY

Email: new.mobility@knipping.de

Phone: +49 173 5271169

KNIPPING KUNSTSTOFFTECHNIK GESSMANN GmbH

Daimerstraße 21

D-74211 Leingarten

Germany